Moving to a sustainable world

pro’green

Protechnic pro’green is our voluntary strategy dedicated to creating a better world. By focusing on three pillars: CSR engagement, sustainable supply chain (Product & Technology), and circular business (Eco-design), we drive towards progress and minimizing our environmental footprint

Protechnic pro’green global approach

Recyclable thermoplastic adhesive

Adhesives matching your material’s composition

Composition materials can be recycled in end of product life if all adhesives & substrates are from the same polymer family.

Mechanical recycling

Mechanical recycling is a method of reprocessing waste materials into new products using physical technics.

- Similar based materials (EX: 100 % polyester-based or 100% Polyamide- based) can be recycled mechanically.

- Mechanical recycling allows to reuse the waste and conserve ressources promoting sustainability

Chemical recycling

Chemical recycling converts plastic waste into raw materials through specialized chemical processes.

-

It breaks down plastics into their original components for reuse

- Chemical recycling often involves complex and energy-intensive processes, which can be costly and require specialized equipment.

Eco-design

Crafting a sustainable tomorrow. Together.

Through our eco-design approach, Protechnic aims to minimize environmental footprints throughout the lifecycle.

In the thermoplastic adhesive industry, Protechnic selects raw materials (bio based) for the development of adhesive products & applies the same level of care/attention/awareness/selectiveness on all the value chain(production, supply chain, logistics…), with environmental considerations.

Protechnic selects carefully raw materials (ex: bio-based, recyclable) for adhesive development, and extends the same standard across the entire value chain, including production, supply chain, and logistics, all with a strong focus on environmental considerations.

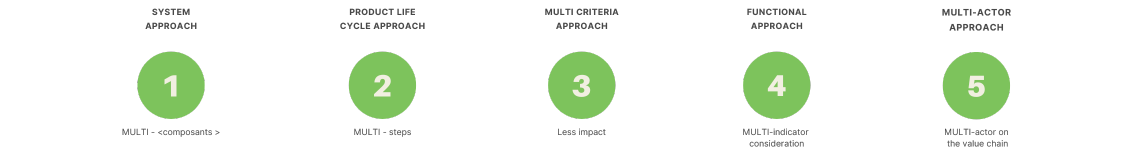

Our approach to Eco-Design

CSR Engagement

Protechnic Cares: Thinking Smartly. Impacting Positively.

As part of Bemis Group, Protechnic is dedicated to the core principles of responsible and sustainable business practices, which are central to our mission to contributing to a better world. Explore our CSR initiatives to observe the tangible and the positive difference we’re making within the communities we serve and for the partnership we’ve built with our customers, suppliers, and collaborators.

Environment

Caring for future generations.

Society

Building a community that shares the same values.

Economy

Preserving long term partnerships.

Our strategy for a better futur.

Adhesive that make you reduce your waste & process steps

Less adhesive waste

Compared to water-based liquid or powder adhesive,1 m² material can bond 1 m² substrates, there will be less waste during the application process.

- Width, weight can be customized

- Material can be cut easily depending on the needs

Less process steps

- Easy to start the machine

- Don’t need technical workers

- Optimized Roll to roll lamination process, fast and efficient

Looking for a reliable & stable partner?

41 Avenue Montaigne

68700 CERNAY – France