Introduction

Acoustic panels are essential in modern design, providing noise reduction and improved sound quality in offices, public spaces, and homes. To manufacture these panels effectively, different materials—such as foams, nonwovens, fabrics, and fibers—must be bonded for specific functions. This is where thermoplastic adhesives play a vital role. Thanks to their versatility and efficiency in roll-to-roll lamination, they have become the go-to bonding solution in the acoustic panel industry.

What Are Thermoplastic Adhesives in Roll Form?

Thermoplastic adhesives are solid glues that become tacky and bondable when heat is applied. Once cooled, they form durable, stable bonds without the need for solvents. They are available in different formats, with the most common in acoustic applications being

-

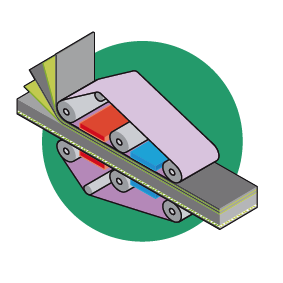

Web adhesives – lightweight nonwoven structures that provide uniform coverage and bonding across large surfaces.

-

Net adhesives – open mesh materials that maintain air permeability while ensuring strong adhesion

Both options are eco-friendly, easy to handle, and designed for fast industrial lamination processes. They can be applied using either a flatbed or a calender machine, making them highly versatile in production lines.

The growing demand for acoustic solutions has made efficient and sustainable bonding technologies—like thermoplastic adhesives—more important than ever.

Why Use Thermoplastic Adhesives in Acoustic Panels?

-

Efficient Roll-to-Roll Lamination

Perfect for continuous production, thermoplastic adhesives activate quickly under heat, making manufacturing faster and more cost-effective.

-

Strong and Flexible Bonding

They bond porous and lightweight materials without compromising the panel’s acoustic performance. -

Eco-Friendly & Solvent-Free

Safer for workers and more sustainable, since no solvents are required. -

Design Freedom

Web and net adhesives allow bonding of irregular shapes and lightweight substrates without adding unnecessary bulk.

Industry Example: Protechnic France

Protechnic, a French leader in adhesive solutions, is globally recognized for its web and net thermoplastic adhesives. The company delivers innovative bonding solutions for industries such as automotive, construction, and interior design, where acoustic panels play a critical role in sound control.

Applications in Acoustic Panels

-

Wall and ceiling panels for offices, schools, and public spaces

-

Office separators for better workplace acoustics

-

Cabinet insulation for noise reduction in furniture and appliances

Conclusion

As acoustic panels gain popularity across offices, homes, and public spaces, the need for efficient, sustainable bonding methods is rising. Thermoplastic adhesives—particularly in web and net formats—offer manufacturers a fast, reliable, and eco-friendly solution for producing high-performance acoustic panels. With industry leaders like Protechnic France driving innovation, thermoplastic adhesives will remain at the core of acoustic panel manufacturing for years to come.

If you want to have the product catalog, don’t hesitate to write us an email: commercial@protechnic.bemisworldwide.com