Automotive manufacturers have specific needs when it comes to assembling materials. As the market evolves, the need for versatile and sustainable bonding solutions becomes essential. In addition, car interior becomes increasingly customized.

This is where thermoplastic adhesive in roll comes into play.

Thermoplastic adhesive able to bond any material in automotive

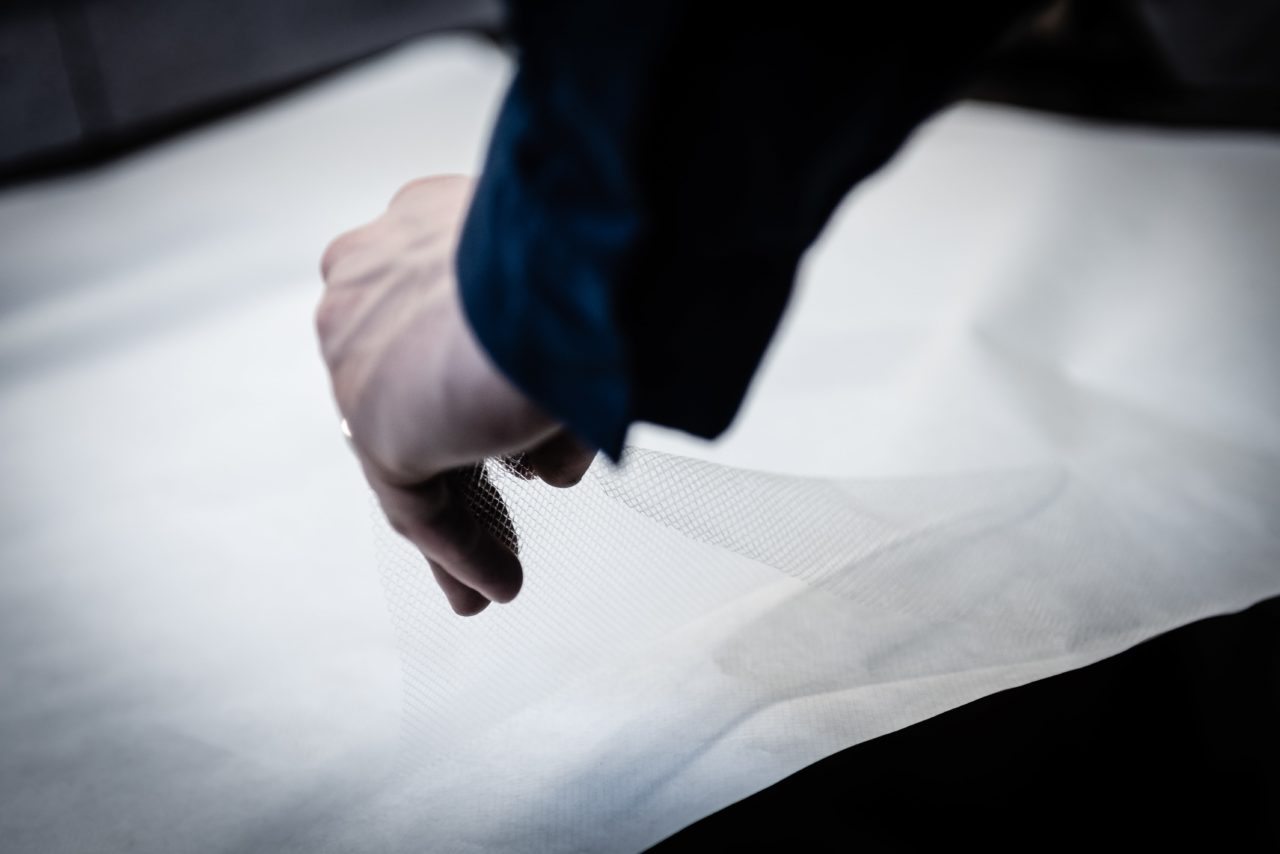

Whether you’re working with leather, alcantara, microfiber, PVC, PU artificial leather, foams or technical non-wovens, hotmelt adhesives in roll ensures a seamless and durable bond allowing the best and lasting comfort for the end user. Thermoplastic adhesive provides a consistent and durable bonding. It plays an active role in stabilizing materials so the shape of the part remains the same through time.