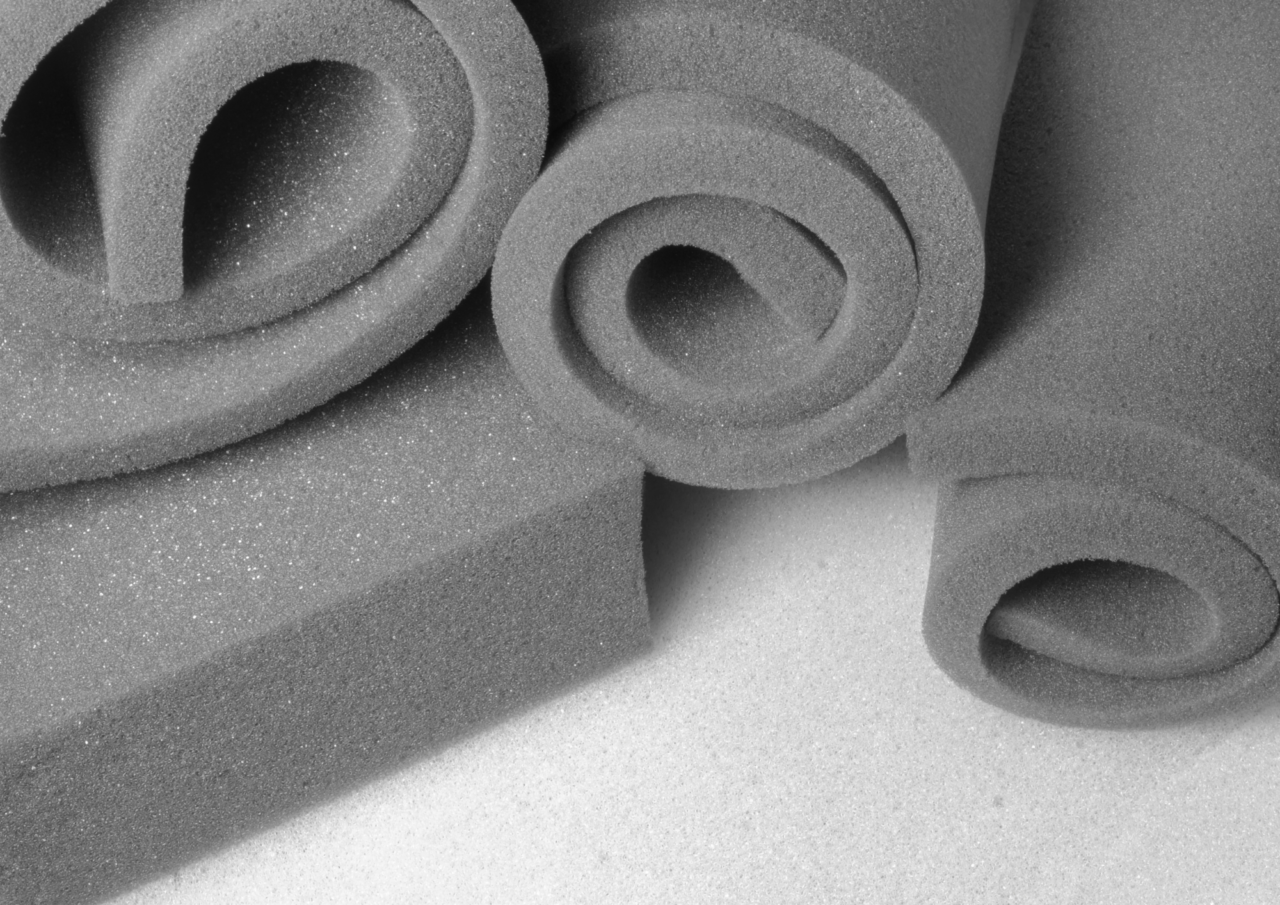

For foam materials, selecting the right adhesive solution is crucial for achieving efficient and sustainable bonding results. One versatile option is thermoplastic adhesive in roll, which effectively bonds various materials, including foams and other technical substrates. In this article, we will explore the important role that this type of adhesive plays in various applications using these materials.

The Versatility of Thermoplastic Adhesives

Thermoplastic adhesives shows versatility by creating durable bonds across different types of materials, such as foams, 3D spacers, felt, non-wovens, technical textiles, or leather. This bonding addresses diverse manufacturing needs, with net, film, and web structures contributing to the improvement of applications in automotive, upholstery, footwear, leather goods, composites, building, and more. Roll-to-roll lamination method allows very low waste and clean results, 1 meter of adhesive equals to 1 meter of laminated material.