VOC-Approved Thermoplastic Adhesives

Environmental consciousness is increasing in many industries and regulations are more and more stringent when it comes to emissions. Industries like automotive & transport, aircraft & aerospace, upholstery, and interior furniture are looking for sustainable solutions.

Volatile Organic Compound (VOC) approved thermoplastic adhesives are part of these sustainable options, offering performance and environmental responsibility.

VOCs are organic chemicals that evaporate at room temperature and can have effects on air quality and human health.

Solvent-based adhesives are a way less promoted solution for bonding in these sectors, because of their high VOC content that poses significant concerns.

Recognizing these challenges, Bemis | Protechnic decided to engineer thermoplastic adhesives with very low VOC emissions.

Bemis | Protechnic commitment to sustainability with VOC-approved thermoplastic adhesives

At Bemis | Protechnic we commit to this principles with a careful selection of raw materials with very low VOC emissions. Furthermore, our dedication to your sustainability led us to create thermoplastic adhesive products with bio-based content up to 91%.

Bemis Protechnic VOC-approved benefits across Key Industries

The adoption of VOC-approved thermoplastic adhesives offers various benefits for industries:

- Automotive & Transport: In vehicle interiors, where passengers and drivers spend a lot of time in enclosed spaces, low VOC emissions are crucial for their health and comfort.

Thermoplastic adhesives are ideal for bonding interior trim, seating, headliners, and carpets, contributing to improved cabin air quality.

Example: Bonding door panels with a VOC-approved thermoplastic film ensures a secure trim without releasing harmful fumes into the vehicle cabin.

- Aircraft & Aerospace : The aerospace industry have strict safety and environmental regulations. VOC-approved thermoplastic adhesives offer a lightweight and high-performance bonding solution for interior applications in aircraft and aerospace such as seating, composite panels, or carpet.

Reduced VOC emissions contribute to a healthier cabin environment for passengers and crew. The application offered by adhesive film and web also minimizes adhesive waste.

Example: Utilizing a VOC-compliant thermoplastic web adhesive for bonding seat fabrics ensures durability and comfort while meeting stringent aerospace VOC regulations.

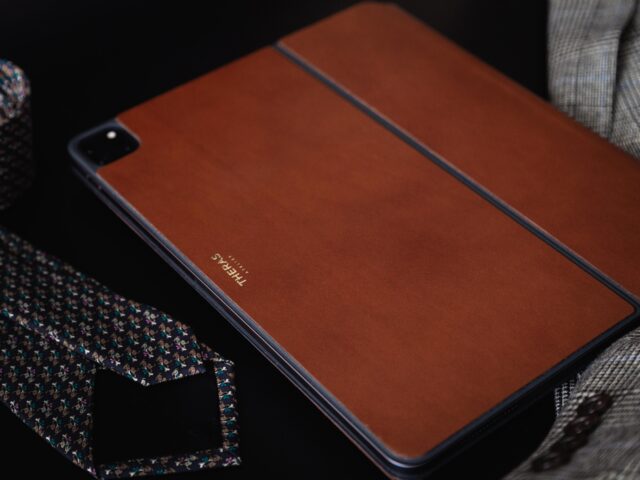

- Upholstery & Interior Furniture: In the furniture and upholstery sectors, VOC emissions from adhesives used can impact indoor air quality in homes and offices.

VOC-approved thermoplastic adhesives provide a clean and efficient bonding method alternative, contributing to healthier environments. Our thermoplastic adhesives offer strong adhesion to various materials like foam, fabric or leather.

Example: VOC-approved thermoplastic adhesive to bond foam layers in a sofa cushion ensures comfort and durability without compromising safety.

Would you like to know more about our VOC-approved adhesive range?

Contact us at: commercial@protechnic.bemisworldwide.com