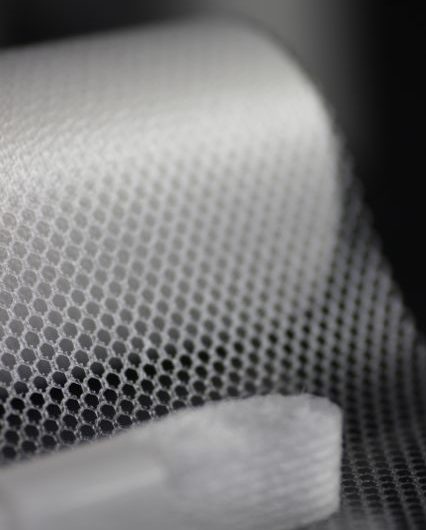

Dry lamination is a technique employed in both automotive and industrial applications to bond two or more flexible substrates without the use of solvent-based adhesives or liquids. The adhesive utilized in this process often comes in roll form, which can have various structures like webs, films, or nets.

Using a roll-to-roll method, dry lamination facilitates quick bonding of different substrates. The bonding between the laminated layers is primarily achieved through thermoplastic adhesives such as polyolefin, polyester, co-polyester, co-polyamides, TPU, and specialty blend polymers.

For this roll-to-roll technique, the production line must be equipped with rollers to accommodate both the film or web and the various substrate layers. The thermoplastic adhesive is placed between these layers, and a laminating calender—with adjustable heat and pressure settings—ensures the materials bond correctly.